5" Gauge Sleepers

| Quantity | Price per item | Discount |

| 301 items | £0.57 | 10% off |

| 601 items | £0.56 | 11% off |

| 1001 items | £0.54 | 14% off |

Over scale sleeper designed for stability when passenger hauling. It is ideal for both standard and narrow-gauge locomotives and rolling stock. Choose between single or dual gauge.

A slightly over scale sleeper that is designed for stability when passenger hauling. Although of not any particular scale, it is highly suited for both standard and narrow gauge locomotives and rolling stock.

The sleepers are injection moulded from high grade engineering polymers, making them extremely durable, rot, frost and UV resistant.

The system is very quick and easy to assemble, no drilling is required. The sleepers are moulded with pilot holes for the screws, plus when used with PNP Railways rail chairs automatic gauge widening is built-in.

The sleepers have hollow ribbed undersides to allow the ballast to enter, making an extremely stable base.

The following rail fixing options can be used with this sleeper:

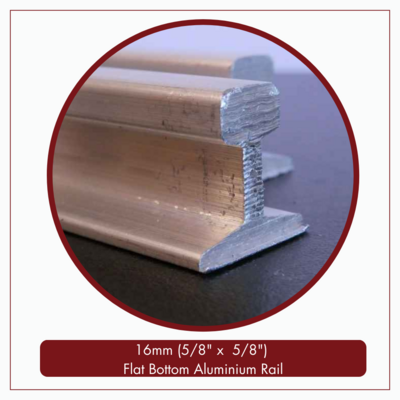

- Screw Fit Chair to suit 16mm (5/8" x 5/8") flat bottom aluminium rail or (21mm) 2lb yard steel or aluminium rail.

- Clip Fit Chair to suit 16mm (5/8" x 5/8") flat bottom aluminium rail.

- Bar Rail Chair to suit 10mm x 20mm steel bar rail.

This sleeper is also available as part of a kit. Available in 1.25m (4ft), 2.5m (8ft) and 10m (32ft) lengths. The shorter lengths are ideal for standing the loco on while building, or indeed displaying the finished model. The 10m Kits are ideal for laying in the garden or for use as a portable track.

Both systems are easy to assemble and benefit from selectable gauge widening, the advantage of the Clip Fit chairs, is that no screws are required, just slide the chairs onto the rails, and push into the sleepers.

5" Gauge Sleeper Dimensions:

(L) 250mm x (W) 33mm x (H) 25mm

Recommended Sleeper Spacing :

100mm centres

Material - Polypropylene

All plastic sleepers and rail fixings in the PNP Railways range are manufactured from high-grade engineering polymers that are extremely durable and resistant to rot, frost, and UV radiation. UV stabilizers are added to the base polymers to help prevent UV radiation degradation and extend the life of the products.